1850s Art Nouveau Joseph Sankey & Jones Bayliss Tray & Server

Code: 11934

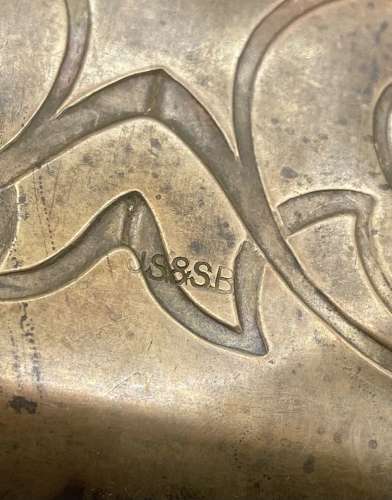

For sale is a Antique late 1850s Art Nouveau floral Copper Afternoon Tea Cake Tray And Cake Server, maker marked J.S&J.B which stands for Joseph Sankey & Jones Bayliss. This is a rare piece of British made art nouveau design, unfortunately this tray is in rough shape, the handles are missing, needs a good clean, and several small dings so please see the photos for more details. The missing handles, can’t be seen from the top or sides only when turned over can this be seen, and it’s likely that these handles were added after manufacture because of the led solder used to attach them. This mainly needs a good clean now.

Some history of the company is below:

The origins of the business of Joseph Sankey & Sons Ltd are in the partnership agreed between Samuel Jackson and Joseph Sankey in 1854 for the production of blank trays from tinplate. Joseph Sankey was born in Bilston in 1827. After he was orphaned by the death of his father in 1836 he attended the Royal Orphanage School at Wolverhampton, and was apprenticed to John Duncalfe, tray blank maker of Hall Street, Bilston, when he was fourteen, where he was taught design and mechanical drawing. He was later employed by the Birch brothers who made tinplate trays that were then 'japanned'.

After the failure of this business, two of the senior workmen, Charles Harthill, and Samuel Jackson, set up their own firm in Middlefield Lane, and employed Joseph Sankey. Charles Harthill died in 1854, when the firm owed £800 to Jon Bates, a sheet iron merchant. Bates secured possession of the plant and tools of the firm as security for the debt. He recognised Sankey's skills and determination and persuaded Jackson to take him into partnership in 1854. This partnership took the decision to concentrate on the production of blank trays stamped from tinplate and then sold to japanners. Jackson & Sankey produced trays of different shapes and sizes, and had several 'best-selling lines'. The business had to repeatedly remortgage the firm's premises in Dudley Street to finance expansion, though was able to repay the loans.

In 1867, Joseph Sankey acquired land in Albert Street, Bilston, next to the back of the Dudley Street workshop. He had paid Samuel Jackson for his share of the partnership in 1861, but Jackson continued to work for the firm as a foreman in the blank tray shop. Large workshops were built at the Albert Street Works and steam-powered drop stamps were installed, enabling the firm to produce heavier gauges of metal to make frying pans and kettles. Workers were recruited from Birmingham and Wolverhampton to manufacture these products.

Joseph Sankey went into partnership with Richard Chambers and John Page to buy a rolling mill and ironworks at Stonefield in 1862 or 1863 in order to gain closer control over supplies of tinplate and sheet iron. The business was renamed the Bilston Iron Company. From 1874 the business concentrated on the manufacture and sale of a range of hollow-ware items including dish covers, tin boxes, lamps, lanterns, milk churns and chocolate moulds, and a huge variety of stamped or pressed metal products including bath tubs, metal life buoys, and fire shovels. The firm also developed a significant export business - exporting 'Cassada' pans to Brazil and bowls to india, Ceylon and China. Cassada pans were shallow dishes in which coffee beans were dried.

Until the late 1860s, Joseph Sankey did most of the book-keeping and paid the wages himself. In 1874 the firm had 65 employees. In 1871, Sankey's eldest son, John William Sankey (1855-1913), left school to work in the offices, and he took on the firm's accounting. He became a partner in 1878 and took on more managerial responsibilities to expand the firm. Sankey's second son, George H. Sankey (1865-1934), joined the business in 1884. Two other sons worked for the firm briefly, before pursuing other careers. Joseph Sankey appears to have lived on the premises of the firm until the early 1860s, when he had a new home built, Goldthorn House, on Goldthorn Hill, Wolverhampton, where his sons were brought up. Joseph Sankey died in 1886.

The firm was contacted by a London iron merchant, Robert Jenkins, in December 1886, who had done some research into the possibility of making dynamo armatures from charcoal sheet iron discs and consulted Siemens the electrical engineers. Jenkins thought that the firm's existing machines could be adapted to manufacture electrical laminations and persuaded Siemens to place an order for electrical stampings in 1887 through the firm Harold & Jenkins. By 1890, contracts had been concluded with several others firms, through the agents Harold & Jenkins, who were appointed Sankeys selling agents on a commission basis.

In 1893 the partnership of Harold & Jenkins dissolved, with Robert Jenkins continuing to work as an agent for Sankeys. The firm made improvements to their stampings during the mid-1890s, and abandoned charcoal iron in favour of a metal steel sheet which was given the brand name 'Lohy'. This arrangement lasted until 1941, when the company decided that agencies were inappropriate, and a new company, Robert Jenkins & Sankey Ltd, was formed. John William Sankey admitted his two younger brother, Frederick Ernest Sankey and George Herbert Sankey, to the partnership in July 1891, as a result of the continuing expansion of the business. The name of the firm was changed to Joseph Sankey & Sons. The business continued to manufacture electrical laminations and also developed its traditional pressing and stamping business. Joseph Sankey & Sons acquired a number of smaller businesses during the 1890s including Edward Morris & Sons which manufactured sugar-making utensils; Huttons, which manufactured nickel plated trays; the Sanitary Bath Company, which made copper-clad steel; and the established firm of J. H. Hopkins & Sons of Granville Street, Birmingham, which was a hollow-ware and japanning company that had the 'Sphinx' trademark, subsequently adopted by Sankeys. The japanning side of this business was sold, and the stamping and pressing concentrated at the Albert Street Works in Bilston.

In 1890, Sankeys patented a process under the name of Neptune Ware'. This involved running tinplate through colour rollers to undercoat both sides. After being embossed and painted, the ware was blanked out to the final shape. The technique had been borrowed partly from America by John Sankey. This ware was used for waiters' trays, ash-trays, cups, children's money boxes, cake baskets and other small articles. 'Neptune Ware' was a huge success and part of the Albert Street Works had to be expanded to cope with the growing demand. During the 1890s, Sankeys were also producing more kettles than any other British company and made their manufacture cheaper by using steel, which could be pressed into shape more easily, speeding up production. In 1900 the ongoing expansion of the business led to the purchase of a derelict iron and tinplate works at Bradley, originally established in 1833 by Thompson, Hatton & Co. After the business failed, the site was sold to Sankeys. Most of the existing buildings were demolished, and new shops were built for slotting machines and keyway cutters in order to transfer the manufacture of electrial laminations to these renamed Bankfield Works from Albert Street. To meet the growing needs of the Bankfield Works, the Manor Rolling Mills at Ettingshall were purchased from Stephen Thompson Ltd in 1904. These premises were known as the Manor Works. The two plants were connected by the Shropshire Union Canal. Some of the mills had been converted by Thompson for the supply of electrical sheets, so Joseph Sankey & Sons was able to exploit this machinery and ensure a supply of sheets for the firm's other works.

In September 1902, Joseph Sankey & Sons was floated with an authorised capital of £200,000 divided into 10,000 ordinary shares of £10 each and 10,000 5.5% preference shares of £10 each. George and Frederick Sankey were apointed directors, together with John Chambers, who had risen through the business to become, in effect, the company secretary. John Sankey became chairman. This post passed to his brother George after his death in 1913. Other members of the family were subsequently appointed to the board during the First World War years. In 1906, Sankeys and the Hadfield Steel Foundry Company of Sheffield entered into an arrangement whereby Sankeys were granted an exclusive licence to obtain or manufacture special electrical steel referred to as 'stalloy' as a registered brand. In 1909, Sankeys sub-licensed John Lysaght to roll sheets under Hadfield patents at their Orb Works. The firm also granted the Brymbo Steel Company, near Wrexham, a licence to make steel bars and blooms under the Hadfield patent on condition that these would then be sold to Lysaghts for rolling into sheet. Through these arrangements, Sankeys were able to increase their control over the supply and quality of their raw material outputs. Sankeys began to supply pressed body panels for automobiles in 1904, as well as wood and iron coachwork, necessitating the construction of wood-working body shops at Albert Street. The firm was also exporting body panels to Paris and New York by 1906. In 1908 Sankeys developed and patented the first pressed and welded, detachable motor car wheel, the 'All Steel Wheel'. The firm also took orders for other automotive components, and demand increased rapidly, putting pressure on the Albert Street Works.

In 1910, Sankeys purchased the former factory of the Castle Car Company, at Hadley Castle, near Wellington, Shropshire. This company had supplied tramcars, and some of the machinery was still intact, making it possible to manufacture body panels there. In 1911, the body shop was transferred from the Bankfield Works, and the wheel shop moved from the Albert Street Works. The Hadley Castle Works was extremely successful, with the best-selling products being the Sankey wheel which was sold extensively to British car makers, and pressed sheet steel car and charabanc bodies. Sankeys contemplated entering into an agreement with Thomas Tilling of Peckham and W. A. Stevens of Maidstone which would involve the manufacture of omnibuses and lorries through the sale of the Hadley Works to the merged business, which would be called Hadley Engineering Company Ltd. A prospectus was prepared, and shares offered to the public, but the minimum subscription was not met, so Sankeys withdrew from the project. See DB-25/1/4 for papers relating to this venture. The firm was consistently successful during the Edwardian period; despite short-lived strikes and depressions, turnover and profit was increased. Sankeys lost large numbers of workers to the armed forces at the outbreak of war in 1914, and several branches of the business were severely affected. However, the firm received substantial orders from the Ministry of Munitions during the First World War, and from November 1915, the Albert Street Works became a Controlled Establishment under the authority of the Ministry of Munitions. Albert Street and Hadley Castle produced field kitchens, mine hemispheres, aeroplane parts and bombs, rifle grenades, mortar bombs anti-submarine bodies and shell bodies. They also produced steel helmets. In order to cope with this increased demand, Sankeys took on large number of female workers during the war years. Sixty-nine employees were killed during the war, including Sydney Sankey (1889-1915), the eldest son of John William Sankey, who was killed at the Battle of Loos. He was an engineer, and had been one of the directors of the company.

The photographs make up part of the description, I will describe the item the best I can and to the best of my knowledge. As the buyer please view the photos carefully before purchasing. Guaranteed original or money back. This will be sent via 1st class signed for if the value is under £60 and anything over will be sent via express 48 Parcelforce or Royal Mail special delivery and dispatched within two to three working day’s. Also happy to post world wide.